Band Adjustment

Richard, here is the second pass at the document, ready for review.

Overview

The bands on a Kamado are involved in the hinging function needed to open and close the lid and to form a correct and complete seal when the lid is closed. These bands are carefully adjusted, at the time your Kamado is built, to provide a moderately airtight seal between the base and the lid.

This is confirmed at the factory by seeing if a sheet of paper is held firmly at several points around the full circumference of the Kamado when the lid is closed. There should be at least moderate resistance to having the paper pulled out, and we adjust the bands until that benchmark is met.

Performing the Paper Test

-

The paper test is an easy and reliable measure of how well the bands are adjusted. Here’s how to do it.

-

Fold a sheet of ordinary 20 pound paper (photocopying paper, laser printer paper, letterhead, etc.) in half.

-

Open the lid slightly, insert the paper, and close the lid.

-

Pull gently and see if there is at least moderate resistance to the paper being pulled out (or, even better, if it is impossible to pull out).

-

Repeat this process at approximately 45-degree intervals all the way around the Kamado. Pay particular attention to the hinge and handle areas.

-

If the Kamado fails the paper test at one or two places but shows some “grip” at those places, it needs a MINOR band adjustment.

-

If the Kamado fails the paper test at MORE than two places OR if it fails badly at one or two places, it needs a MAJOR band adjustment.

Why Do the Bands Need Adjustment?

-

One reason a band adjustment might be needed is that on rare occasions, rough handling during shipping causes movement of the bands from their factory-set positions. This results in a Kamado having an unacceptable leakage of air from the outset which can make low-temperature control difficult. In extreme cases, it makes it difficult or impossible to extinguish the fire at the end of a cooking session.

-

The other reason is that years of frequent use result in the bands moving enough to affect the integrity of the seal.

In addition to difficulty in temperature and fire control, another symptom of band leakage is uneven deposits of grease on one area of the gasket that separates the lid and dome.

It is important to understand that if there is leakage, it is not caused by warping or other changes in the ceramic surfaces of the lid and base. These areas have been surfaced at the factory and they will maintain a virtually airtight seal if the bands are properly adjusted and an adequate gasket is in place. Leakage simply means that the bands have slipped and need adjustment.

Counting the Bolts

Before attempting to adjust the bands on your Kamado, you MUST determine whether it is a four-bolt or a ten-bolt-through model. The procedure for band adjustment differs for each of these two bolt arrangements.

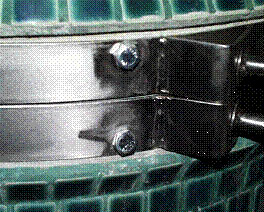

All Kamados have four bolts (two on each side) that mate the front and back parts of the upper (lid) and lower (base) bands:

Some models have six additional bolts near the hinge that pass through the bands and through holes drilled in the Kamado lid and base.

If your Kamado has the six additional bolts, you have a ten-bolt-through model, otherwise you have a four-bolt model.

Band Adjustment Four-Bolt

There are two methods of performing a band adjustment in the field, we'll call them "Major" and "Minor".

Do a Major adjustment when any of the following a

- There are major visible air leaks.

- The paper test fails at three or more points.

Do a Minor adjustment when any of the following a

- There are small air leaks.

- The paper test fails at one or two points.

For a Minor band adjustment you need to only perform Step 7 of the Major procedure outlined below.

This “Major” procedure begins with Step 1 and is basically the same as performed in the factory when the bands are first installed or the bands have been removed for shipping or handling.

TOOLS REQUIRED—

- Spring handler: a homemade dowel or PVC pipe with a slot cut in the end that allows the bolt to be removed while holding the spring up in the tube. This is easily made from a piece of one-inch dowel, broomstick, or PVC pipe.

- Two [size]-inch wrenches for loosening and tightening the bolts

- A hammer and a small block of hard wood, for “tapping” the bands. A piece of pipe, a rod, or a heavy screwdriver will also work.

- You MAY need to provide one or more new [size]-inch bolts, depending on whether or not the originals are reusable.

Step 1:

Raise the lid of the Kamado as high as possible and tighten both stopper handles on the spring prop tubes. This will securely hold the lid up.

Step 2:

Use the spring handler tool to push the spring up from the bottom of a prop tube. Once the pressure on the bolt is removed, unscrew the bolt that keeps the spring from exiting the tube at the bottom. Slowly release the tension on the spring, and remove it from the prop tube. Repeat on the other prop tube.

Step 3:

Loosen the stoppers and carefully lower the lid. Keep in mind that the springs are removed, so the lid will be heavy. Don't let it drop!

Raise and lower the lid, adjusting the upper and lower bands until they are level with the rims of the base and lid, all around. This can be done by tapping the bands until they slide together and are even with the lid and base surfaces.

The goal is not to have the bands touch each other, but rather to have them perfectly level with the top of the ceramic surface of the lid or base. In a proper adjustment, there should be about an eighth of an inch of space, representing the thickness of the gasket that separates and seals the base and lid.

This adjustment can often be done by tapping the bands with a hammer and piece of wood, without even needing to loosen the bolts.

If tapping will not move the bands together, it might be necessary to loosen the band bolts slightly, allowing the bands to be moved, and then retighten.

Step 4:

Do the paper test to see if further adjustment (tapping) might be necessary. Raise and lower the lid several times to be assured there are no gaps.

We insert a folded sheet of newspaper or writing paper to test and make sure the paper cannot be pulled out at any location between the lid and base of the Kamado. This procedure indicate where any potential leaks are.

Step 5:

Tighten the band bolts as tight as possible. Sometimes new bolts might be required. We tighten the bolts until they and the bands form a 90 degree bend. This is the key step in a permanent band adjustment.

We know that tightening the bolts this tight might be concern you, and that you might think it could damage the ceramic walls or the Kamado itself, but it will not. Your Kamado's modulus of rupture or compressible strength is remarkable and will withstand this tremendous force

Step 6:

Raise the lid to its fullest, tighten the stoppers and insert the springs into the prop tubes. To insert the springs, use the a dowel or PVC pipe with a slot (as mentioned above) to push the spring into the prop tube far enough to insert the retaining bolt.

Step 7 (also the one step necessary for a Minor adjustment):

Loosen the stoppers, lower the lid and perform another "paper test." If there is a slight looseness in the paper test, this can be corrected by tapping the bands with the bolts tight and the springs in. See the examples below.

Examples of leaking (paper test) and suggested corrections:

- Front (at handle). Lid does not close all the way down.

Correction: Tap the hinge upward. Alternating left hinge brace & right.

- Leaking at Hinge Area.

Correction: Tapping is done lightly with the band bolts TIGHT and springs IN. It is considered a final adjustment or minor adjustments after use for some time. Or in the case where shipping or moving has change the band position slightly. If it is difficult to tap the bands for adjustment, a slight loosing of the band bolts should be done. After adjustment and paper test the band bolts should be re-tightened or tightened.

Summary

Hopefully, this will be the last adjustment ever needed. However, sometime in the future it is possible to torque the bands sufficient to cause bands to slip. For example, having the lid held partly open with one prop stopper and leaning on the lid. In this case there is hundreds of pound torque twisting one side while the other is held firmly. Normal use should not require band adjustment.

Frequently Asked Questions

-

What tools are necessary?

-

If a complete band adjustment (removing the springs) or installing the bands after they have been removed would require a dowel or other such instrument, the size of the inside of the prop tube with a slot cut for the retaining bolt.

-

An ordinary hammer.

-

A simple devise to tap on such as a bar, bolt, pipe, rod, heavy screwdriver or similar are all good. Also a very piece of very hard wood works.

-

Two end wrenches to tighten the 4 band bolts.

-

-

How often is band adjustment necessary?

Possible once or twice a year. Often, never. On average, once every two years or after shipment or moving. -

How long does it take to do the adjustment of the bands?

Approximately 10 to 20 minutes where the springs have been removed. If only a slight leak in the paper test and springs remain in and bolts remain tight, it would only a minute or two. -

Is adjustment of the bands necessary if only a small leak of 1/32 of an inch or so? Or if a lot of “low and slow” cooking is desired and/or when the Temperature Controller (Guru or other) is used.

Nothing is damaged on the Kamado or the operation, by a small gap. However, maintain very low temperatures (under 200 degrees) or smothering the charcoal out after cooking it might be necessary to have a band adjustment. -

How do I know if the bands need adjustment?

Visually, the bands should be close together and are NOT above the surface of the lid and base. I.e. very little gap between the upper and lower metal bands. Excessive smoke between the bands (some smoke is normal when the lid is closed quickly with the damper and draft door closed.) Cardboard or paper test as discussed above. Charcoal does not smother out with damper and draft door closed. -

How long have there been Kamado adjustment issues?

From the day Richard designed the first bands 40 years ago. Prior to metal bands, we raised the lid by the ceramic handles cast in the lid. All Kamados, prior to our new Kamado design, did not have compression springs to assist in raising the heavy lid and provide the safety feature of preventing the lid from slamming down. Without compression springs, there is less tendency for the bands to slip. Careful adjustment of the bands is a small price to pay for the convince and safety of the prop assists. -

What is the most common problem in adjusting the bands?

Not tightening the 4 band bolts tight enough because customers fear that over tightening the bolts will damage the Kamado. This should not be a concern. -

What do I do if all my attempts to adjust fail?

A: Please call or email service@kamado.com. We have solved all unique band adjustment problems.